Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Shandong IPRE Inspection Technology Co.,ltd

Based on the principle of the magnetic interaction between the leakage field and the magnetic powder, the multi-functional magnetic particle flaw detector can accurately and intuitively display the shape, position, size and severity of the defect, and determine the nature of the defect. The instrument adopts a variety of magnetization methods and can detect various parts of the workpiece. It is widely used in the detection of defects in petroleum, chemical, metallurgy, shipbuilding, aviation, railway and other fields. instrument.

IPRE@CDX-Ⅲ series magnetic yoke flaw detector is a new type of magnetic particle flaw detection equipment designed and produced by our company, which absorbs the advantages of similar products both domestically and internationally. The use of external magnetic field magnetization method makes the instrument have the advantages of small volume and light weight. A highly integrated circuit enables a device to perform all the functions of several original devices, and the instrument can be equipped with four types of probes: A, D, E, and O.

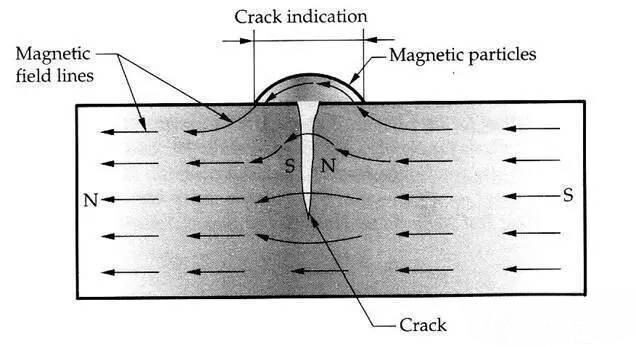

Place the object of ferromagnetic material to be tested in a strong magnetic field or pass a strong current to magnetize it. If there are defects (cracks, folds, inclusions, etc.) on the surface of the object or near the surface, the magnetic field lines will generate magnetic flux leakage near these defects. , when the magnetic powder with good magnetic permeability (usually magnetic iron oxide powder) is applied to the object, the leakage magnetic field near the defect will attract the magnetic powder, pile up to form visible magnetic powder traces, and form visible magnetic traces under suitable light , so that the position, size, shape and severity of the continuity are not shown, and the defect is revealed.

| name | Horseshoe yoke fillet weld probe | Crossed yoke probe or rotating field probe | Electromagnetic Yoke Probe | Ring probe |

| Type | A | E | D | O |

| Profile | Movable joint inclined magnetic head, equipped with work light: especially suitable for detecting irregular surfaces and complex shaped workpieces. Equipped with an electromagnetic yoke fillet weld detector, the probe adopts a movable joint and can be freely adjusted for a wide range of use | Crossed yoke probes or rotating field probes The head can be magnetized in all directions at one time Flaw detection, walking rollers and working lights can be Improve flaw detection speed. Equipped with a rotary Rotating magnetic field flaw detector with fast probe speed ,high detection quality |

A variety of movable joints, with high magnetization. An electromagnetic yoke fillet weld flaw detector is equipped, and the probe is characterized by high magnetic conductivity, high magnetization, etc | Equipped with a ring flaw detector, It is produced when the coil is energized The principle design of strong magnetic field , suitable for shaft rods, tubes. Complicated work such as roads and bolts Sectional flaw detection or demagnetization of parts |

| Lifting force | AC≥5kg,DC≥18kg | AC≥8kg | AC≥6kg,DC≥20kg | 1800TA |

| Probe pole distance | 20-160mm | 110mm | 60-220mm | 150mm |

| weight | 2kg | 3.5kg | 2.5kg | 3kg |

Company

Production

Contact

We look forward to cooperating with you.